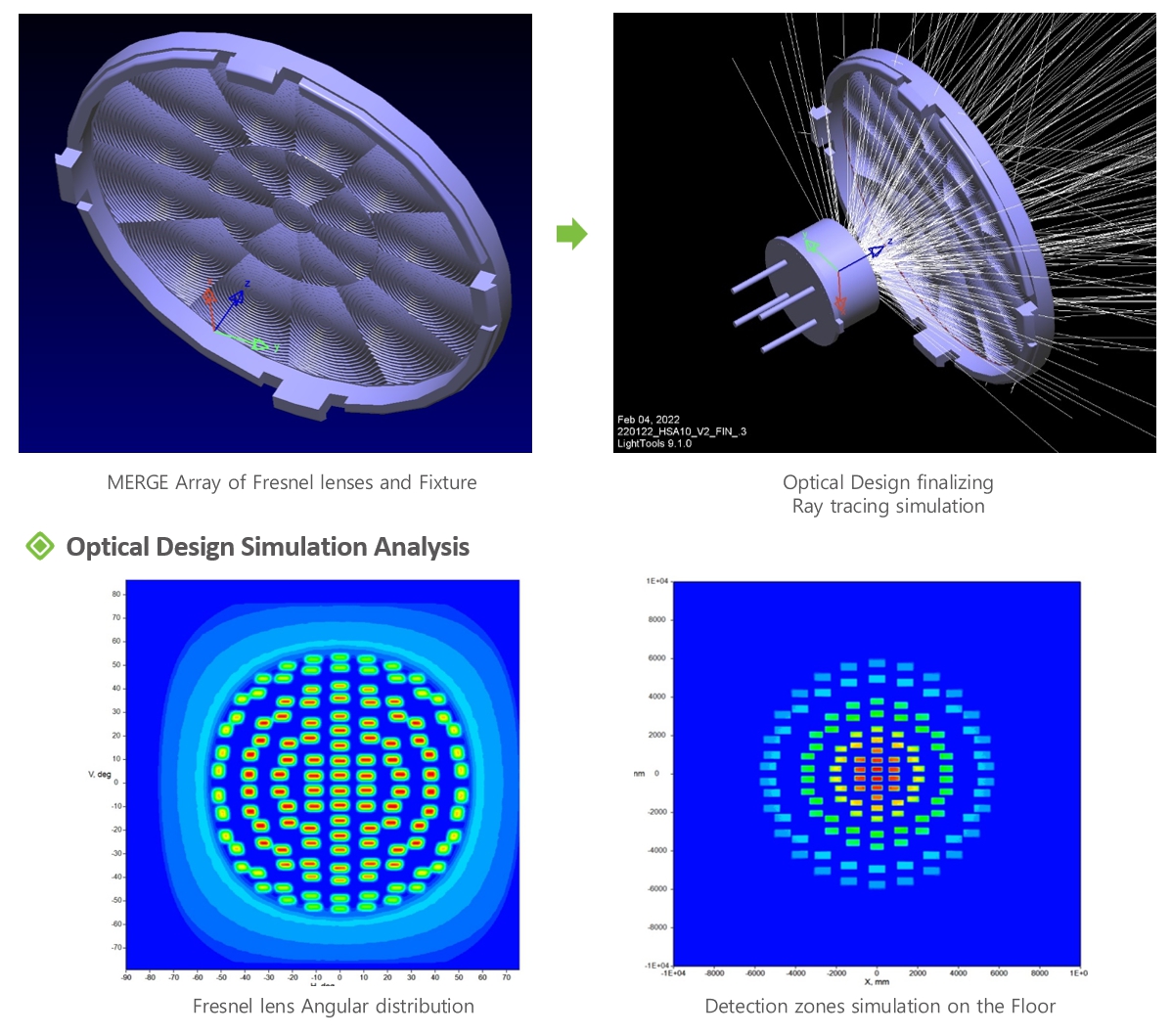

Lens simulation and System design consultancy

|

Short Description |

Performance simulations and consulting system level design |

|

Description and feature list |

Simulations and materials selection for TMOS sensor lens and cover materials Consulting of design arounding lens/cover assembly, lens/cover integration |

|

Proposed Engineering Service (if selected) |

System Architecture;System Design;Hardware Design;Software Design;Firmware Design;Verification;Testing;Safety;Certification;Quality Mgt;Consulting; Mechanical design; consulting; Hardware design;system design |

This is a service that related with optics for sensors, such as motion, presence, LiDAR and etc.

Please feel free to contact ashton@fresnelfactory.com or you can fill out “Design request form” for further question.

Typical service time is from 2 weeks to 4weeks.

Please check below information for better understanding what kind of “Lens simulation and System design consultancy”

- Understanding what is the role of lens in the system

- Define your requirement

- To remove gap between simulation and real product

- Understanding what is the role of lens in the system

The optical sensor, such as TMOS detects light intensity within its detectable area. The detectable area consists with field of view, distance and direction.

Role of lenses are changing those factors according to applications and use cases.

Not only performance side, but also lens works as aesthetic parts. A active area of lens should be exposed to outside without any blocking. From this reason, optic engineer is better to join a beginning of mechanical and industrial design phase.

As example, TMOS sensor itself can detect 6meter distance, but TMOS sensor with PF63-10 can detects 16meter distance.

As you can feel lenses are very important in Optical sensors. most of the optical sensors has Lenses inside of their mechanism.

Check the No. 5. Define your requirement for details.

- Define your requirement

The TMOS sensor and lens must be exposed on the front of the product. Therefore, it is necessary to determine the direction of the industrial design before starting the optical design. If only a draft of the ID is completed, it is very important to consult with an optical designer before starting the optical design with the completed ID. This is because the size and shape of the lens are determined based on the optical performance of the device to be developed, such as detection distance, installation environment, and detection angle. Considering that the lens must be exposed on the front of the product, the involvement of an optical designer before ID finalization is essential.

- To remove gap between simulation and real product

Even if your design partner is a highly skilled optical designer or a mold and injection technology expert, there can still be a difference of 20% or more between predicted design performance and actual performance in reality. This is often because optical designers may not understand molds and injection, and mold and injection technology experts may not understand optical design. In addition, depending on production conditions and additives, there may be an additional 5% or more difference in performance. Therefore, it is essential to evaluate the manufactured optics and the device in which the optics are used to confirm whether the goals have been achieved and to tune them accordingly.

- Contact

USA : Frank Yim / frankyim@fresnelfactory.com

Global : Ashton / ashton@fresnelfactory.com