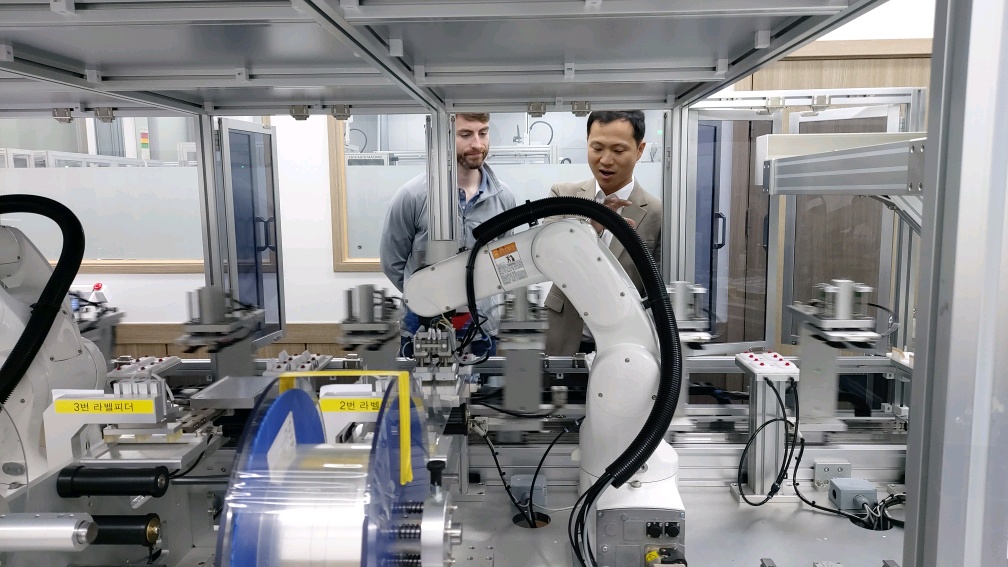

Inspection of automated production equipment

On April 25, 2023, a representative from Company A, a global business customer of Fresnel Factory Korea, visited the Fresnel Factory. The visit included a comprehensive overview of the entire process, starting from the optical design of infrared sensor lenses to mold manufacturing, injection production, and quality inspection and attachment of double-sided tape using robots.

During the visit, the importance of maintaining a uniform production environment was emphasized, and the indoor temperature and humidity control system, as well as the air circulation system for managing fine dust and airborne pollutants, were introduced.

Furthermore, specific equipment related to injection molding machine of Sumitomo for high-precision injection was also presented and discussed.

During the visit, the Quality Control procedures, including FT-IR measurement, were introduced and discussed. FT-IR measurement is an essential part of the Quality Control process to assess the quality and characteristics of materials.

Additionally, detailed discussions were held regarding the specific criteria and standards for Quality Control. These discussions aimed to ensure that the products meet the required quality standards and specifications set by both Fresnel Factory Korea and Company A. By establishing clear quality criteria, it becomes possible to consistently monitor and evaluate the products to ensure their adherence to the desired quality levels.

The demonstration of laser engraving for mass production application allowed us to assess the depth and quality of the logo engraving according to the specific requirements of the customer. By showcasing this process, we were able to verify the suitability and progress of the laser engraving technique in meeting the customer's needs. This demonstration provided a valuable opportunity to address any concerns or adjustments necessary to ensure that the final products meet the desired standards and expectations of the customer.

The Scaled Performance Test (SPT) Machine, one of the distinctive features of Fresnel Factory, was also introduced during the visit. The SPT Machine is a measurement device developed by Fresnel Factory after four years of research, and it complies with the international standard IEC 63180 for infrared optical sensors. It allows for the measurement of the optical performance of infrared sensors with high precision and repeatability, surpassing the previous human-based measurement method (NEMA standard). Moreover, it enables measurements under various environmental conditions, providing enhanced accuracy and reliability in assessing the quality of the sensors.

The visit was a valuable opportunity for building stronger trust between Fresnel Factory and A customer from the United States. Fresnel Factory is committed to fulfilling the needs of its customers and will always strive to provide the best possible solutions.

Fresnel Factory specializes in producing IR lenses for optical sensors using injection molding machines and automated production systems. The production capacity is currently at 2.7 million lenses per month, with the automated systems capable of producing 1.2 million lenses per month using technologies such as 6-axis robot arms.

Starting from the second half of 2023, the production capacity will increase to 4.1 million lenses per month, and the automated systems will be able to produce 2.5 million lenses per month using technologies such as 6-axis robot arms.

Ashton Myung Joong KIM

CEO of FresnelFactory Inc.

USA : +1 415 779 5317

MOBILE : +82 10-5248-4630

No posts found

Write a review