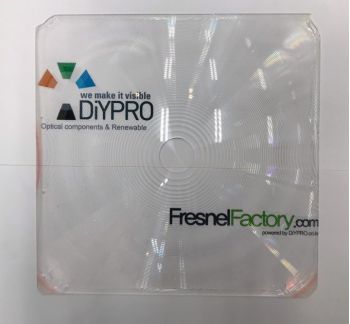

Fresnel lens

Fresne lens have been used in many fields recently because they can exceed the limitations of thickness and area of existing lenses. Also, it can be made according to the shape that the customer wants, and in special cases, it can be made with a cover lens. Recently, there was a request from a foreign company, KEEPEN and Russia's ARSIBEX, to produce...

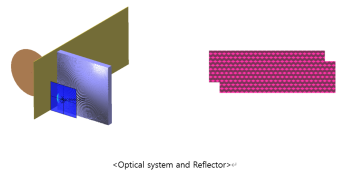

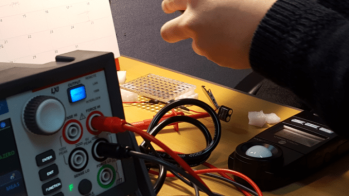

Recently, more and more people are asking about security optics. Usually, security optics use invisible infrared rays. It is constructed by transmitting infrared light to receive light coming back from an object. There was also an inquiry about the development of a security optics system in FresnelFactory, So we proceeded with the design of an...

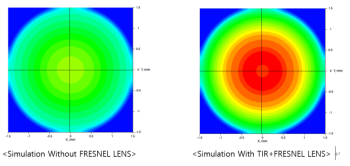

TO INCREASE LIGHT EFFICIENCY FRESNEL LENS DESIGN WITH TOTAL INTERNAL REFLECTION STRUCTURE FOR NEAR INFRARED SENSORS

Recently, the development of Fresnel lens for NIR(Near Infrared) is increasing. Near infrared, also called NIR (Near Infrared), has various applications. Used in ADAS, Internet of Thing (IoT), Time of Flight (ToF), beauty and healthcare. In addition, the demand in the sensor sector is steadily increasing. FresnelFactory Inc. also recently...

PRESENT NEW NIR SOLUTION IN 2020 SPIE PHOTONICS WEST

Fresnel Factory Co,.Ltd exhibited various Fresnel lens for NIR(near-infrared), FIR(Far-infrared) and Motion sensor(PIR, Passive-infrared) at the 2020 SPIE Photonics West. We had a meeting with 83 companies and planned cooperation research with a global optics company. <SPIE Photonics West FresnelFactory booth> <...

INCREASING DEVELOPMENT OF NEAR-INFRARED (NIR) FRESNEL LENS

Recently, the development of Fresnel lens for near infrared ray is increasing. Near infrared, also called NIR (Near Infrared), has various uses. Used in self-driving cars, Internet of Thing (IoT), Time of Flight (ToF), beauty and healthcare. Near infrared has a wavelength of 0.75 ~ 3um and has 12 times higher penetration than...

glassy carbon mold for glass press molding upto 2000° C

glassy carbon mold for glass press molding upto 2000° C Introduces the development of glassy carbon mold, which is 99.2% carbon, capable of glass press molding with high melting point glass upto 2000 ° C. In the past, the lens was thermoformed with low melting glass material by using DLC (Diamond-like carbon) to increase the heat...

New optic development example by AR Fresnel lens

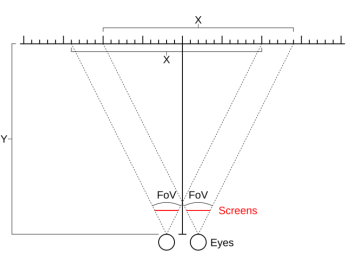

This is an example of developing Fresnel lens for Augmented Reality(AR) according to the development STEP of FresnelFactory Co., Ltd. Proceed as follows to develop high-performance lenses quickly 1. Confirm customer requirements and set development goals The customer had a requirement of more than Field Of...

Cast fresnel lens for near-infrared

I would like to know which point you want to check. NIR Transmittance of Material Verifying the optic design of the lens For 1. We can provide a sample Fresnel lens. Even it has different Focal and size from your design. It is specially tuned for NIR wavelength and has high hardness and heat resistance. The...

We introduce case of mold production for injection molding of ultra-small precision optical lens. In order to make injection molding of ultra-small precision optical lens which uses five sides of hexahedron as effective lens surface, we adopt fine mold processing, Surface roughness of 50nm or less, and tunnel gate. Hello, This is Fresnel Factory...

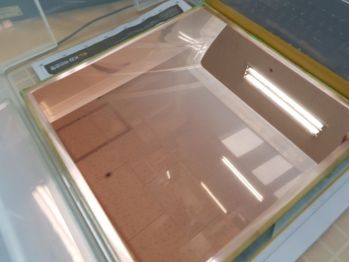

Fresnel lens manufactured by casting mold

Introducing Fresnel lens manufactured by casting mold. While improving optical lenses to be used as 3D optical elements for TV-sized glassfree 3D optics of 55 inches in Fresnel Factory, we introduced Fresnel lenses for the first time by introducing a casting mold that improves optical characteristics for obtaining high-quality images Hello,...

Linear fresnel lens customzing from Canada

This customer is looking for linear type fresnel lens for concentrate photovoltaic. Below is email from the buyer. ------ I am looking for the pricing a custom made lens. The technical information is below: - Diameter: 23 in - Type: Angle bending (12 deg) - Material: PMMA - Thickness: 3mm - Pitch/groove: standard (we are open...

Producing mold for Prism

How are you? Today I'm going to introduce the mold for prism which is produced recently. Optical prism which contains micro pitch is using for a lot of applications such as redirecting film for windows, chromatic dispersion, hologram instruments and back light units. Inquiry about mold to Myungjoong Kim, CEO Tel +82 70 7605 0693...

Production of Fresnel lens for ELS CPV

Today, what I want to introduce is the use of Fresnel lens to improve the generating efficiency of solar cell which we manufactured and supplied sample to L company. These days, we can see price indication with crystal which is used in the E-book of big hyper market. E-book needs electricity although power consumption is small compared with...

CCTV linked Fresnel lens for IR lighting apparatus

How are you? The product we will introduce you today Fresnel lens used in the IR lighting apparatus linked with CCTV. By application of Fresnel lens at the IR lighting apparatus designed to be able to distribute light in the short distance, we made the distribution of light in the 10 ~30m distance possible. As the result of this...

Manufacturing CPV Linear Fresnel Lens

So far this year, inquiries on the CPV photovoltaic generation is in the increasing trend not only from domestic market but also from overseas. In such trend, it is a Linear Fresnel Lens for CPV which we supplied to a electric power company of UK in March. Specification is as follows; 1. Lens Size = 1,000mm(width) x 500mm(length) 2. Linear...

◈ Optical design of SPOTLIGHT for broadcasting lighting and tool making of lens product: SPOTLIGHT for broadcasting lighting use: broadcasting lighting The product we would like to introduce is SPOTLIGHT for broadcasting lighting. Broadcast lighting shall keep the value of color rendering and color temperature even with the application of lens...

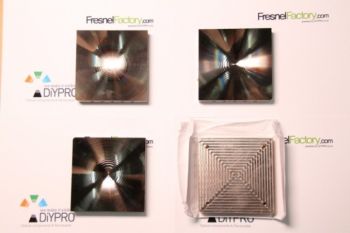

Production of CPV Lens Mold Core

◈ Production of CPV LENS MOLD CORE product : CPV Lens Mold Core usage : condensing solar cell module Lens size : 120x120mm(4 cavity) Focal area size : 6x6mm Light concentration magnifying rate : 400 times The product now we want to introduce is CPV Lens Mold Core. As client requested light concentration magnifying rate more than 300...

Prism load and Fresenel lens supplied to KIST.

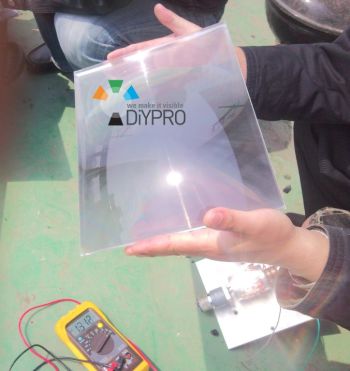

DIYPRO delivered prism load and Fresnel lens to Electronic Material R&D Group, KIST. It was custom-made by us to support their research purpose. Prism load was made of quartz to make it withstanded in the high temperature, and Fresnel lens was customized the products which was developed for the concentrating photovoltaic purpose....

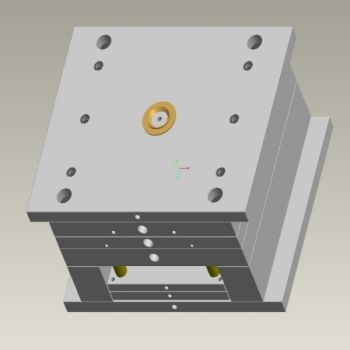

Fresnel Lens Injection Mold 3D Drawings and Products

Injection mould is vital for fresnel lens that is our main product. There are two types of producing it; Hot press and injection, let me introduce the latter. The injections and products designed for order production ※ Injection 3D Drawings (front) (decomposition) ※ injection ※ The product produced by...

Fresnel for COB LED

My name is XXX and i'm trying to get a straight beam of light with my (100W) LED array. (Bridgelux RS) I'm trying to do this for almost one year now with many different lenses. But i'm stuck and can't get a good spot on the wall. (straight beam of light) (near 0 degree) That is why i contact you. Your company seems very...

Very Large Fresnel Lenses

very large fresnel lenses I am interested in your capacity to design and manufacture a very large diameter (1.5 - 2m diameter) fresnel lenses. If you are able to produce such items, can you please give me a very rough estimate of the costs involved in producing a very small quantity of these? We would be looking at quantity under...

Custom Fresnel Lens

Custom Fresnel Lens I am working with Michigan State University on a solar energy project. We are looking to find a company that can manufacture a custom fresnel lens for our project. We need a lens with a diameter of at least 24''. We are having trouble finding this big of a lens. Can your company help us do this? Also we are...

700 degrees Celcius large Fresnel lens

Customer Have a happy new year. I would like to purchase a huge Fresnel lens (I saw them on your website it was 460 or 480 US dollars). I will pay the due amount by my credit card (Paypal account is applicable). I wonder such system can reach 650 degrees Celsius under clear sky weather conditions? What is its shipping cost to Turkey? Could...

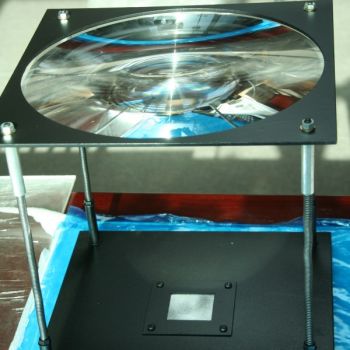

The result of exchanging with small business in Daegu finally appears. We were developing the solar power system of new concept, and the model that is able to be directly tested was produced. We applied our f resnel lens , and increased the condensing rate per cell innovatively. It enables to 0.2...